If your team is still receiving toner, shelving it, labeling it, and then reshipping it to clients, you’re not “adding value.”You need viable 3PL solutions for wholesale OEM toner and ink dropshipping

You’re running a tiny warehouse inside an MSP. That means labor cost, inventory mistakes, shipping delays, and a steady stream of support tickets that all say the same thing: Where’s my toner?

This is exactly why toner dropshipping paired with real 3PL solutions is such a clean lever for MSPs, managed print providers, and copier dealers. You eliminate the box-touching, tighten delivery performance, and scale without hiring someone whose job title becomes “toner babysitter.”

Quick Answers for Toner Dropshipping and 3PL Solutions

The “tell me straight” version—before the deep dive.

What are 3PL solutions for toner dropshipping?

A fulfillment setup where a third party warehouses toner, then picks, packs, and ships orders directly to your customers, often via blind shipping.

Why should an MSP dropship toner?

To cut labor, reduce shipping errors, shrink support tickets, and protect SLAs across multi-site and remote locations.

What should dropship toner include?

Inventory visibility, fast ship cutoffs, tracking automation, blind shipping, clean backorder rules, and a real returns/RMA process.

What’s the biggest mistake MSPs make?

Choosing a “dropship” partner that can ship boxes, but can’t handle exceptions, backorders, or accuracy at scale.

If you want, I can style this same block as a “sticky note” callout, a darker “executive brief” panel, or a tighter 2-column version for shorter pages.

Why MSPs Keep Losing Money Touching Toner Boxes

Toner feels simple until you’re responsible for it across dozens of clients, hundreds of devices, and multiple locations.

Here’s what “touching boxes” actually costs you:

Labor you never priced in. Someone has to receive, check, shelve, pull, pack, and ship. That’s time you’re not billing and not using to land or retain bigger accounts.

Errors that multiply. Wrong cartridge, wrong chip version, wrong yield, wrong shipping address. One mistake becomes a helpdesk ticket, a rush shipment, and an annoyed client contact.

SLA damage. You can be flawless at IT support and still look sloppy because toner arrives late, or not at all. Print is petty like that.

Inventory bloat. Toner sits in closets, cages, trunks, and “that cabinet in accounting.” You lose visibility, you double-order, and you slowly accept waste as normal.

The worst part is the distraction. Supply fulfillment becomes a parallel business inside your MSP. And it’s a business with thin margins, high expectations, and zero gratitude.

If you want to scale managed print add-ons without turning your ops team into a shipping department, you need a system where orders move without your hands on the box.

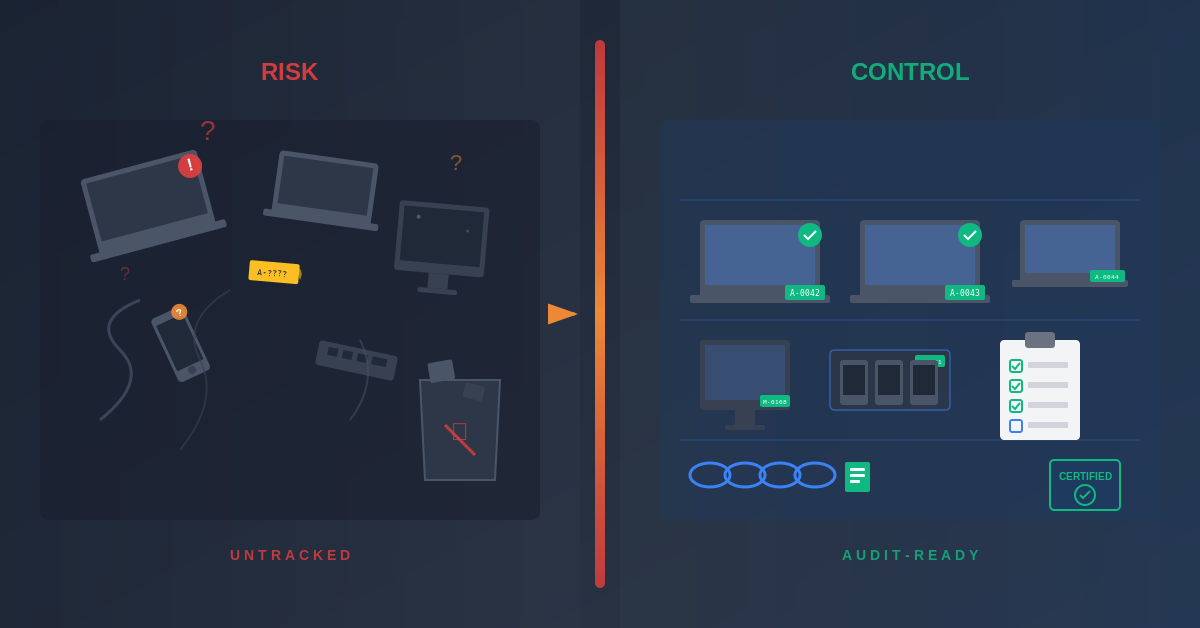

What “3PL Solutions” Actually Means for Toner Dropshipping

A lot of companies say they offer “3PL solutions.” For toner dropshipping, that phrase only matters if it includes the parts that protect your reputation.

At minimum, a 3PL solution should handle:

Warehousing and inventory management (with visibility you can actually use)

Pick and pack (with accuracy controls, not vibes)

Shipping and tracking (with automated confirmations)

But MSPs need more than the minimum.

A real toner dropship setup should also include:

Blind shipping / white label shipping. The box shows up as you, not a random distributor your client has never heard of.

Branded paperwork. Packing slips that match your brand and reduce client confusion.

Backorder logic that won’t blow up accounts. Clear rules: partial ship vs hold, substitutions allowed or never, ETAs that don’t get invented.

Cutoff times and shipping SLAs. If you’re supporting multi-site clients, ship speed is part of service delivery.

A returns/RMA process that doesn’t become your problem. Wrong item, damaged shipment, client changed address, it happens. The partner needs a procedure, not a shrug.

The difference between “we can dropship toner” and “we provide 3PL solutions” is whether the partner can run fulfillment like an operation, not a favor.

Want to talk through toner dropshipping, fulfillment, or a cleaner supply workflow for your MSP? Click here >>

The MSP Toner Dropshipping Workflow That Doesn’t Break

Here’s the difference between MSPs that “offer managed print” and MSPs that actually scale it:

The scalable ones don’t let toner become a side quest.

They treat supplies like a workflow. Not a pile of boxes. Not a frantic email thread. Not “Steve in the back” remembering which client needs which cartridge.

A working toner dropshipping flow looks like this:

A user hits low toner → the request triggers automatically (portal, ticket, alert, or contract threshold) → the order routes to a fulfillment partner → the shipment goes out blind → tracking flows back into your system → billing happens cleanly.

No drama. No “we’ll check the cage.” No “did anyone see the UPS receipt?”

The “real world” part nobody talks about

Your clients aren’t sitting neatly inside one office anymore.

They’re in satellite locations. They’re hybrid. They’re remote. They’re “Susan’s home office in Vermont” and “the warehouse printer nobody claims ownership of.”

Your toner workflow has to be built for ship-to-anywhere reality, which means:

You need clean device-to-SKU mapping (or you’ll ship the wrong cartridge and buy yourself a helpdesk ticket).

You need rules for exceptions (backorders, substitutions, partial ships).

You need a partner that can handle the ugly stuff without making it your problem.

This is where a real 3PL setup becomes more than shipping. It becomes operational insurance.

Backorders: the silent killer of MSP credibility

Backorders don’t just delay toner. They delay trust.

A legit dropship partner should be able to fulfill backorders for OEM toner directly to your customer’s end locations, not dump the problem back in your lap with a shrug.

That one capability alone protects accounts. It keeps you from eating rush shipping costs. It also keeps your techs out of the “print supplies concierge” business.

What to Demand From a Toner Dropship Partner

Plenty of companies can ship boxes.

That’s not the bar.

The bar is: can they run your fulfillment operation in a way that makes you look sharper than you are?

Here’s what I’d treat as non-negotiable if you’re building a dropship toner program for MSP clients.

Operations that protect your name

You want a partner who can say “yes” to specifics, not “we’ll try.”

You’re looking for things like:

Accuracy discipline (not vibes). Pick/pack controls that prevent wrong-item shipments before they happen.

Cutoff times and SLAs you can actually build promises around.

Backorder rules that are defined up front (partial ship vs hold, substitutions never/allowed, ETAs that don’t get invented).

Returns/RMA handling that doesn’t turn into your internal ticket spiral.

Tracking + proof-of-delivery visibility that you can forward to a client without embarrassment.

Logistics range matters more than people think

A lot of MSPs start local and then land a client with multiple sites, or a weird international need, or a remote user base that’s spread out.

That’s why logistics scope matters.

If your fulfillment partner can handle full-service domestic logistics and import/export internationally, you’re not boxed in by geography. You can win accounts that other MSPs avoid because “supplies would be complicated.”

That’s a competitive advantage you can actually sell.

White-glove pickup and delivery (the bonus lever)

Dropshipping solves supplies. But MSPs also run into a different problem:

Stuff has to move.

Old devices. Spare inventory. Project gear. Client cleanouts. That random pile of printers that “might be useful.”

If your partner can do local white-glove pickups around Boston (anything from a van load to a small liftgate truck), you suddenly have a clean answer when a client says:

“Can you get this out of here?”

Even better if they can handle complex packouts (packaging, loading, shipping, and inventory management), because now you’re offering logistical competence, not just toner.

That’s how you turn a one-off supplies conversation into a bigger operational relationship.

Common Failure Modes (and How to Avoid Them)

Let’s save you six months of pain.

Failure mode #1: “We can dropship” means “we have a label printer”

Some vendors “dropship” the way someone “runs payroll” because they have QuickBooks.

If they can’t talk clearly about SLAs, backorder logic, tracking automation, and returns, they’re not a 3PL solution.

They’re a warehouse with ambition.

Fix: Ask them how they handle exceptions. If the answer sounds like improvisation, walk.

Failure mode #2: Backorders that blow up your SLAs

Backorders are normal. Pretending they aren’t is what nukes client relationships.

Fix: Require documented backorder handling. Define whether you allow substitutes. Get ETAs and partial-ship rules in writing.

Failure mode #3: “Helpful substitutions” that create device incompatibility nightmares

If you support mixed fleets, chip versions and compatibility matter. A “close enough” cartridge becomes a repeat ticket.

Fix: Build a substitution policy that defaults to safety. If you allow subs, control them tightly by device family and compatibility rules.

The Quick ROI Math

Here’s the part that turns this from “nice idea” into “why are we still doing this the old way?”

When you stop touching boxes, you stop paying the hidden tax nobody admits is on the P&L.

Every manual supplies touchpoint costs labor.

Every wrong shipment costs credibility.

Every “where’s my toner” ticket costs time your team could spend on real work.

Every delayed delivery quietly weakens renewals, upsells, and referrals.

Even if the hard cost savings feel modest at first, the operational impact stacks fast:

Your helpdesk calms down. Your client contacts stop chasing tracking numbers. Your techs stop getting dragged into supply chaos. Your accounts feel smoother.

And smoother accounts scale.

When Toner Dropshipping 3PL Solutions Make Sense (and When They Don’t)

This model shines when any of these are true:

You support multiple client locations, remote users, or distributed teams.

You sell managed print as an add-on and want it to feel “tight,” not messy.

You’re growing and don’t want to hire someone whose entire job becomes “toner and shipping.”

You want to win bigger accounts without building an internal warehouse.

When it doesn’t make sense:

If your volume is tiny and you’re truly bespoke on every order, a full setup may be more process than payoff.

If you’re unwilling to clean up SKU discipline, you’ll keep tripping over the same mistakes, just faster.

Most MSPs land in the middle: enough volume to feel the pain, not enough structure to fix it.

That’s the exact sweet spot where a real toner dropship partner becomes a growth lever.

If you’re still receiving toner, shelving it, and reshipping it, you’re not delivering “managed print.”

You’re running a small, fragile fulfillment operation inside an MSP.

Toner dropshipping plus real 3PL solutions is the move because it removes the box-touching, tightens delivery performance, and keeps your team focused on what clients actually pay you for.

And if you need more than dropship toner, like domestic and international logistics, OEM toner backorder fulfillment shipped straight to your client locations, or Boston-area white-glove pickup with packout support, that’s where this stops being “supplies” and starts being operational scale.

Frequently Asked Questions: Toner Dropshipping & 3PL Solutions

Straight answers for MSPs, managed print teams, copier dealers, and online resellers who want toner fulfillment that scales without turning your ops team into a shipping department.

1) What’s the difference between “toner dropshipping” and a real 3PL solution?

Toner dropshipping just means the order ships direct to your customer. A real 3PL solution adds the stuff that prevents chaos: inventory visibility, pick-and-pack accuracy controls, shipping SLAs, tracking automation, and a legit returns/RMA process.

2) Can a dropship toner program support remote users and multi-site clients?

Yes, if your workflow is built for “ship-to-anywhere” reality. That means clean device-to-SKU mapping, saved ship-to addresses (and rules), plus exception handling for backorders and partial shipments so your helpdesk doesn’t become a tracking hotline.

3) What is blind shipping / white label shipping, and why does it matter?

Blind shipping means the package shows up as you (or your program), not a random warehouse name your client has never heard of. It protects trust, reduces “who is this?” confusion, and keeps you looking like the operator, not the middleman.

4) How should backorders be handled in toner fulfillment?

Backorders are normal. The failure is pretending they won’t happen. A strong toner dropship partner can fulfill OEM toner backorders directly to your customer’s location and follow clear rules: partial ship vs hold, substitutions allowed or never, and honest ETAs.

5) What integrations matter most for MSP procurement ops?

The goal is fewer clicks and fewer mistakes. Look for practical options like API/EDI, CSV uploads, portals, and tracking updates you can push into your PSA/CRM or ticketing flow. If you can’t get clean tracking and ship confirmations back, you’re flying blind.

6) What should an MSP demand from a 3PL partner’s pick-and-pack process?

Accuracy discipline, not vibes. Ask about scan-based controls, SKU management, wrong-item prevention, cutoff times, and carrier rate strategies. If the partner can’t explain how they prevent mistakes, you’ll be the one apologizing to clients.

7) Do you offer international shipping for toner dropshipping?

If your client base is expanding, international matters sooner than you think. A partner with import/export capabilities and worldwide logistical solutions lets you support distributed teams, cross-border locations, and special projects without rebuilding your process from scratch.

8) Do you offer pickup and white-glove logistics beyond toner?

This is the “bonus lever” that turns a toner conversation into an ops upgrade. White-glove pickups in the Boston area can handle anything from a van load to a small liftgate truck, plus complex packouts (packaging, loading, shipping, and inventory management) when devices and equipment need to move.